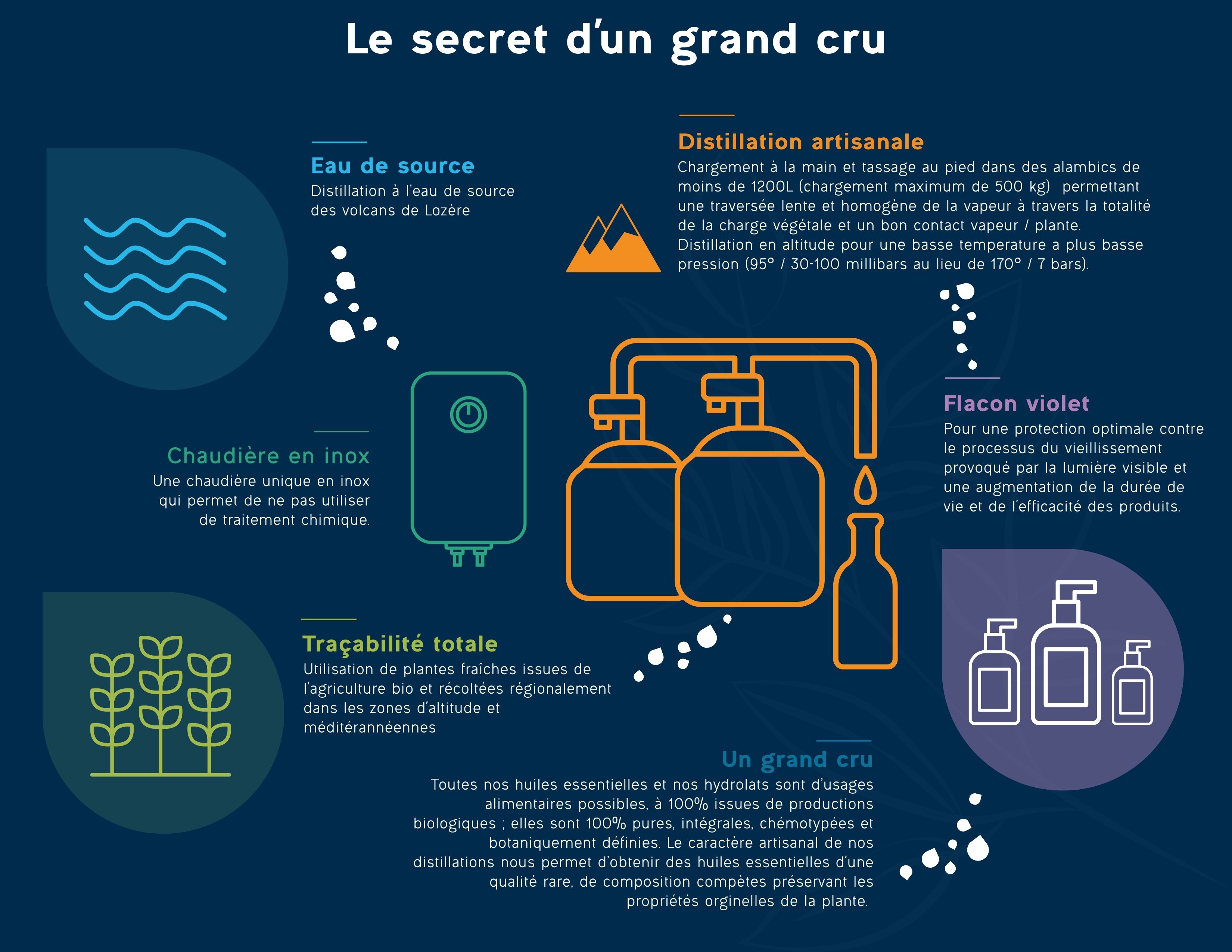

You are never better served than by yourself! At Essenciagua, we are proud to be both a producer and an artisan distiller. We have made the bold choice to distill the vast majority of our essential oils and hydrosols ourselves because it is by distilling that we best control plant extracts.

Slow distillation - Patience as the key word

The art of distilling is a matter of patience. The distillation must be slow and complete with low pressure and low temperature steam to obtain "the totum", the richness and all the complexity of the plant without damaging the most fragile components, without "burning" the light ones. We distill respecting a rule of 1 liter of hydrosol per 1 kilo of fresh plant. Each distillation is fraught with uncertainties and reserves surprises. It’s about remaining humble in front of the plant: the same humility as that of a mountain dweller in front of a summit.

A circular supply network

We only distill fresh plants from organic farming. Organic guarantees an absence of pesticides in our essential oils and hydrosols. Essenciagua has set up a supply chain with certified organic farmers and pickers near the distillery.

Everything is designed in a circular economy logic to promote local resources and reduce greenhouse gas emissions. Essenciagua controls the entire production chain to guarantee exceptional quality. The plant residues from the distillations are composted and used by the distillery's partner farmers.

Our process: Innovation & tradition

At Essenciagua, you enter a land of passion: we have an obsession for perfect distillation.

We distill with Lozère spring water, in unique stills, powered by a food grade stainless steel steam boiler, exempting us from any chemical treatment. This is the essential path to offering you exceptional quality. That of great local wines...

We receive our plants fresh, many harvested within a 150 km radius around the distillery by farmers and pickers from the Occitanie region.

All are in certified agrobiological mode. We load the plants manually into the pre-heated stills: the tamping operation, carried out “by foot”, allows the steam to pass slowly through the entire plant load. Only the loading of a reasonable quantity of plants and therefore the choice of a still of artisanal size allows good mechanical contact between the plant and the water vapor. This process, which is very simple in principle, lends itself very poorly to industrialization.

In the interest of authenticity and quality, our stills have a swan neck closure, also called a retort, and are used for wines and spirits. This specific shape is the signature of Essenciagua. This is what makes our oils and hydrosols unique.

Birth of a grand cru

The essential oils and hydrosols obtained simultaneously are separated after decantation. They are left to rest for many weeks in a cold room in barrels or containers previously steamed at high pressure for perfect hygiene. The storage temperature is constant for slow maturation, as for a good wine. Only then are the oils and hydrosols filtered and packaged in small bottles or flasks.

Still hot when leaving, the plant residues from the distillation are sent to be composted by one of our farmer colleagues. Compost is used in our agricultural processes in organic mode. A whole cycle is thus completed.

Essenciagua purity

Our essential oils and hydrosols are 100% pure and natural, directly from extraction. At Essenciagua, we have always said NO to pasteurization, NO to plant extracts “cut” with water or alcohol, and NO to preservatives. At Essenciagua, quality comes through organic, the demands of craftsmanship and the preference for local produce. We control the entire production chain, which guarantees us optimal and unique quality.

“ Slowly uncork an Essenciagua bottle and close your eyes; you are with your feet in the ground, in the middle of a large lavender field! Let the violet notes spread their aromatic richness and touch your child's heart! ”

Essenciagua Bottles

Did you know that the Egyptians attached great importance to the conservation of their essential oils? They kept them in gold containers or in purple glass vials. Essenciagua was inspired by this use to choose these packaging... in purple glass! High-tech, thick, mass-tinted glasses.

This choice is also based on scientific foundations: To understand them better, we must remember that light is broken down into visible (from blue to red) and invisible (infrared (IR), ultraviolet (UV)) radiation. ..). Visible light is that which comes into play not only in the process of development of life but also in the processes of degradation of living things. Violet glass has the ability to constitute an absolute barrier to visible radiation; UV and IR radiation, for their part, are not stopped by this type of glass. On the contrary, these frequencies, captured by living things, prove to be very important in the processes of cellular communication and the propagation of light energy within biological systems.

Comparative tests on brown glass and purple glass bottles containing rose water have conclusively shown the benefit of using purple glass for the conservation of aromatic molecules. The glasses we have chosen have this dual ability, not only to optimally protect our essential oils and hydrosols against visible light, but also their bioenergy by allowing UV and IR to pass through.